Navistar celebrates expansion of Huntsville powertrain plant

Navistar celebrated the expansion of its powertrain plant in Huntsville on Wednesday, cutting the ribbon on a facility that’s grown by 110,000 feet to support production of new powertrain components.

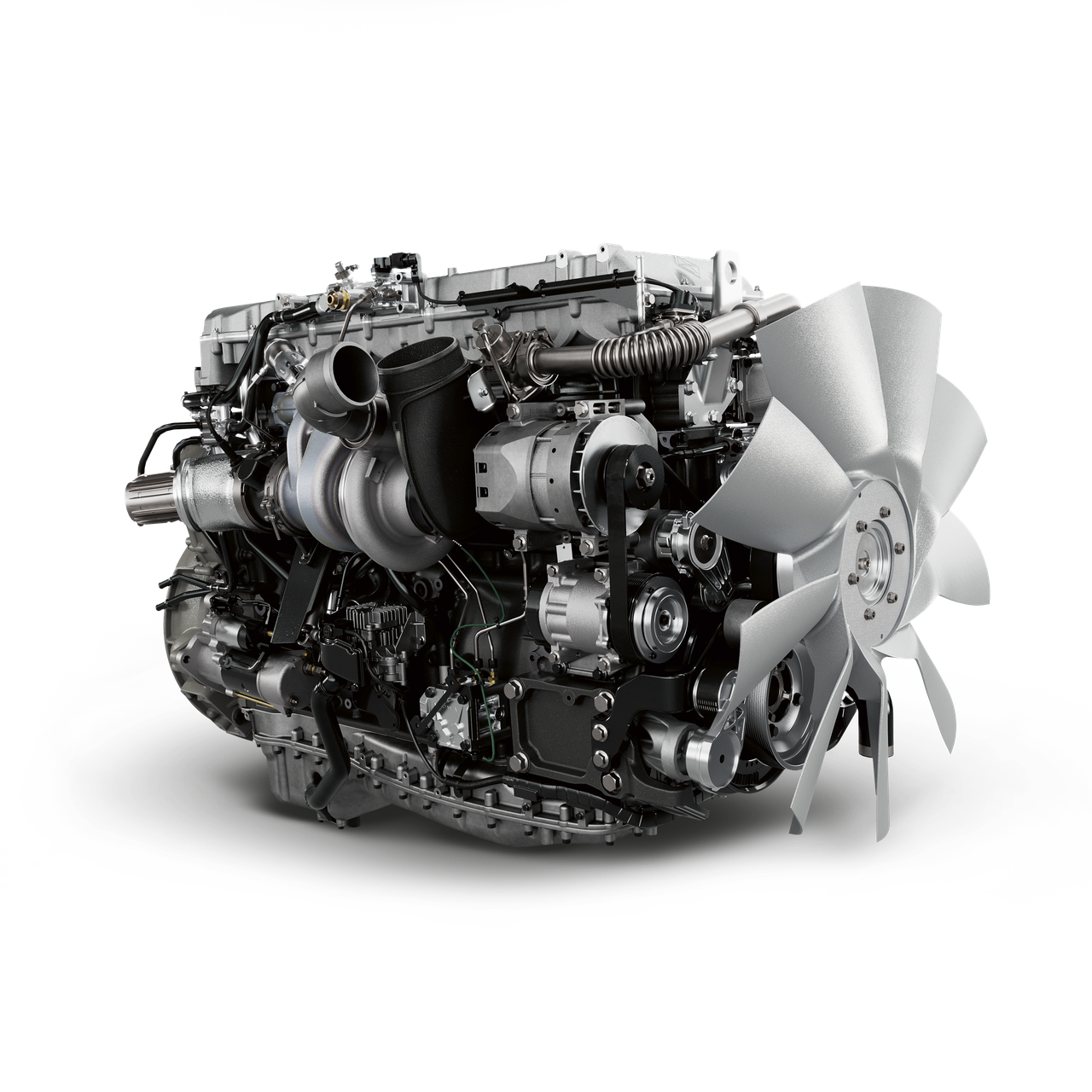

The company, which employs more than 230 people in Huntsville, announced the start of production on the new International S13 integrated powertrain at the Huntsville plant. The International S13 integrated powertrain – composed of the S13 engine, T14 transmission and dual stage aftertreatment system – marks the final combustion product platform that Navistar will develop, the company said.

Navistar is transitioning toward zero-emission vehicles – generally known as electric vehicles.

- Got questions about Huntsville? Use this form to Ask the Lede.

With the new expansion, the now 410,000-sq.-ft. facility has transitioned from a single assembly line to two—one for the T14 Transmission and one for the S13 Engine—along with the incorporation of three major machining lines.

“Navistar is one of those great companies that makes Huntsville go,” Huntsville Mayor Tommy Battle said in the Navistar announcement. “We’re proud that the integrated powertrain is produced in Huntsville and that Navistar has been a strong partner and one of our long-term corporate citizens.”

Altogether, Navistar has invested more than $200 million in the Huntsville plant, which was established in 2008.

“We’re thrilled to unveil the expansion of our Huntsville Powertrain Plant, symbolizing our commitment to innovation and excellence,” Brandon Tucker, director of operations, Huntsville Powertrain Plant, said in the announcement. “Through collaborative efforts with the TRATON GROUP, we are confident to set a new efficiency benchmark in sustainable transportation. The entire team is excited to embark on this journey and build the remarkable S13 Integrated Powertrain that will redefine the industry and power our path towards a more sustainable future.”

Unveiled last year, the S13 Integrated Powertrain, developed in collaboration with the TRATON GROUP, significantly increases operating efficiency, reduces operating costs, and provides greater profitability for customers, the Navistar announcement said.

The 13-liter engine achieves advanced fuel efficiency and performance through combustion efficiency and a reduction of friction and pumping losses, the announcement said. The dual-stage aftertreatment system saves fleet time and enhances fuel economy. Eliminating the exhaust gas recirculation ensures a more complete fuel burn and allows cleaner air to enter the combustion chamber on the intake cycle to mitigate soot buildup.