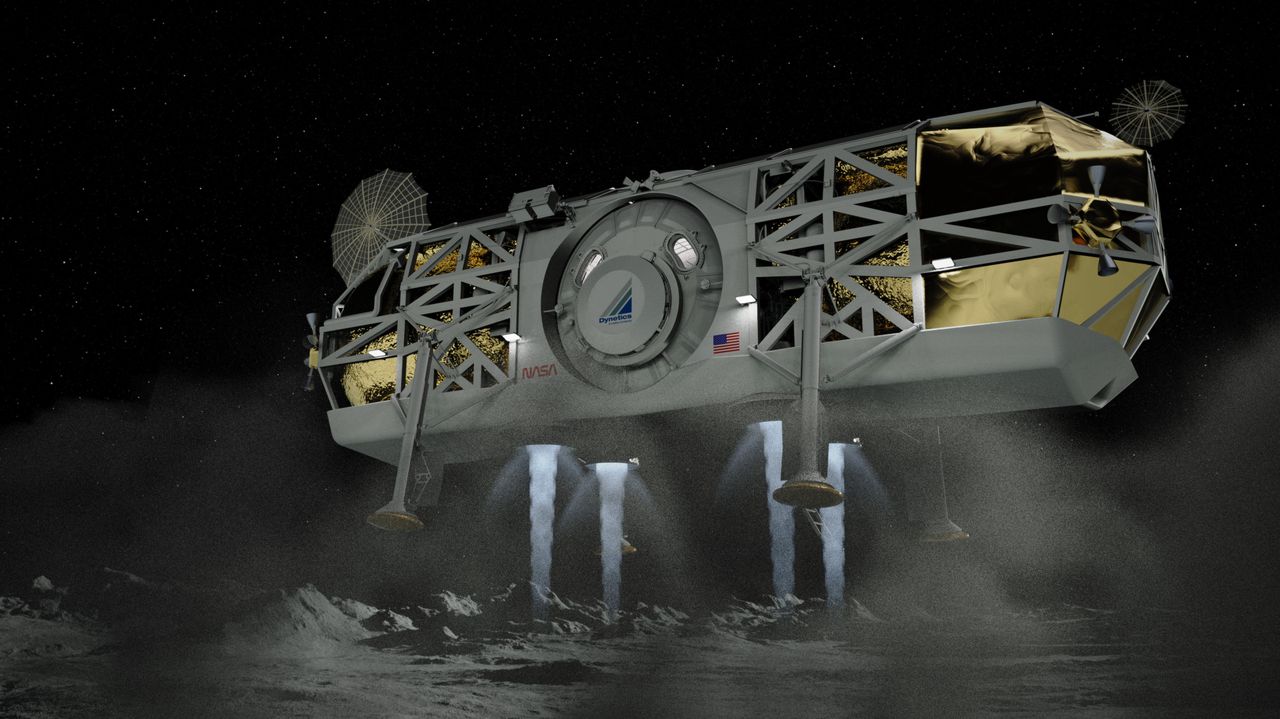

Dynetics: Critical hardware demonstrations done for next NASA moon lander

NASA picked Dynetics of Huntsville in 2021 as one of five finalists to “mature designs” for America’s next moon lander, and the company said today it has built test hardware for more than a dozen technologies the coming Human Landing System will need.

“Our team has continued to work hard over the past couple of years to mature our design and build on lessons learned,” said Andy Crocker, program manager for HLS at Dynetics. “We’ve been fortunate to be able to demonstrate so many key technologies for our lander with full-scale hardware in relevant environments.”

Dynetics, a Leidos company, had said in December it is teaming with Northrop Grumman for its bid to build the lander it is designing. Today, the company talked about what it has designed, built and demonstrated so far to meet NASA’s needs. Those needs include:

Propulsion: This is where the most design tasks existed because the new lander will need main engines and an “overall propulsion system,” Dynetics said. Dynetics’ plan uses liquid oxygen and methane in liquid form for the lander’s main engines and as gases for maneuvering thrusters, among other things.

The company says it has run more than 500 tests of its designs including hot fire tests of an engine nozzle design at Marshall Space Flight Center in Huntsville, NASA’s propulsion center.

Cryogenic fuel transfer: NASA has never transferred super-cold fuel from one spacecraft to another in space, Dynetics said. The company says it has demonstrated a fast transfer method for moving super cold fluids into a full-scale tank has also demonstrated its fuel leakage prevention plan.

“This really heightens our confidence in our propellant transfer approach, which is vital to reducing the risk of our lander architecture,” Crocker said.

Lunar dust control: Moon dust was “a difficult problem for astronauts” in the Apollo missions, Dynetics said. Unlike Earth dust, lunar dust clings and is hard to brush off surfaces. Buildup on a long mission “could render critical components like solar arrays and cameras unusable,” Dynetics said.

NASA itself developed what the company called a “promising solution” that uses electrical charges to remove dust. Dynetics said it has built its own versions of this Electrodynamic Dust Shield and showed they can work. “Our unique micro-fabrication skills made (NASA’s plan) a perfect fit for us,” said Robert Wright, Dynetics space division manager.

Power: Dynetics focused on “high power density batteries” to meet NASA’s landing needs and providing energy to the lander during lunar dark. The company said it demonstrated that advanced batteries can to the job and “an innovative approach to operate the lander through a 14 Earth-day-long lunar night and demonstrated the central enabling technology.”

Docking systems: Dynetics says it is developing a commercial spacecraft docking system usable by multiple systems including NASA’s and commercial space systems.